- Products

- Bimetal Lugs

.png?width=800&height=736&name=Products_%20800%20x%20736_%20Bimetal%20Lugs%20(3).png)

.png?width=800&height=736&name=Products_%20800%20x%20736_%20Bimetal%20Lugs%20(2).png)

.png?width=800&height=736&name=Products_%20800%20x%20736_%20Bimetal%20Lugs%20(1).png)

.png)

.png)

.png)

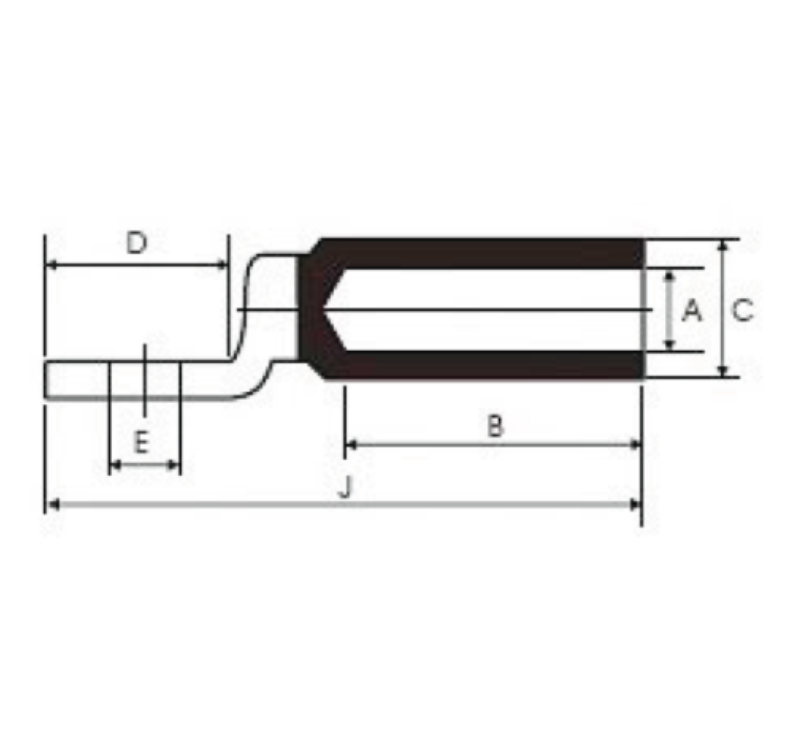

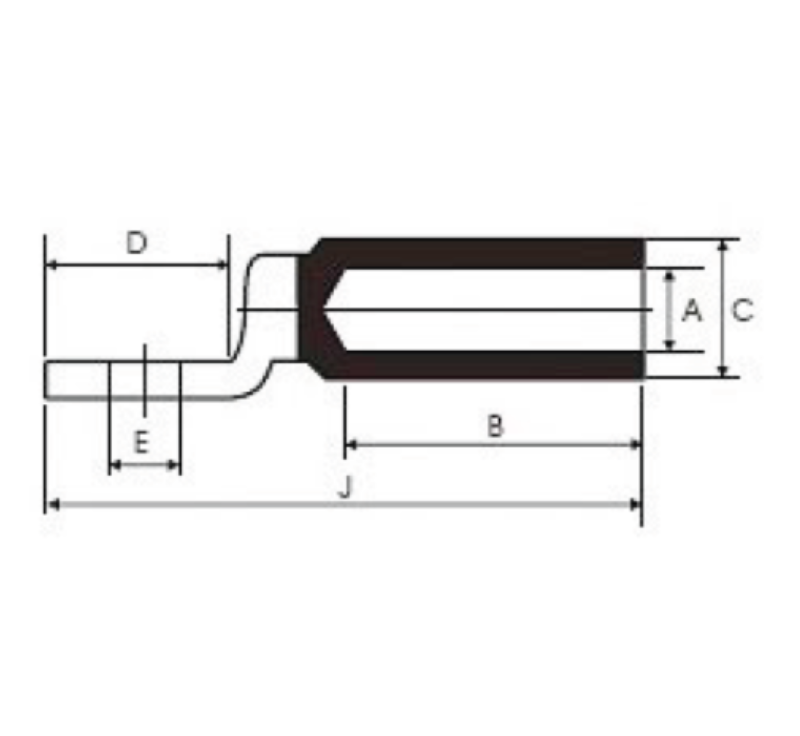

Bimetal Lugs.

Identimark’s Bimetal Lugs offer a trusted solution for connecting aluminium and copper conductors in high-performance environments. Manufactured using electrical-grade materials with a fusion-welded AL/Cu joint, they provide lasting performance, corrosion resistance, and ease of installation—making them ideal for renewable and industrial power networks.

Benefits

Fusion-welded durability

Manufactured with a friction-welded joint between EC-grade aluminium and electro-tinned copper for a reliable, conductive bond.

Corrosion-resistant performance

All copper palms are electro-tinned to BS standards, protecting against oxidation in harsh environments.

Easy conductor insertion

Shock-proof or bell-mouthed barrel entry ensures safe, fast, and efficient wire connection.

Proven under pressure

Crimping test force of 2.0x10⁵ N applied for cable sizes 300–630 mm² ensures safety and strength.

Ready to install

Supplied with jointing compound, end caps, and crimp die information for easy field installation.

Versatile for critical applications

Ideal for solar farms, substations, industrial switchgear, and renewable energy cable transitions.

Options & Features

- Cable Size: 400mm²

- Stud Size: 12mm

- Construction: Friction-welded aluminium barrel to copper palm

- Corrosion Protection: Electro-tinned copper to BS standard

- Accessories: Supplied with jointing compound and end cap

.png)

Specifications

Fusion-welded durability

Manufactured with a friction-welded joint between EC-grade aluminium and electro-tinned copper for a reliable, conductive bond.

Corrosion-resistant performance

All copper palms are electro-tinned to BS standards, protecting against oxidation in harsh environments.

Easy conductor insertion

Shock-proof or bell-mouthed barrel entry ensures safe, fast, and efficient wire connection.

Proven under pressure

Crimping test force of 2.0x10⁵ N applied for cable sizes 300–630 mm² ensures safety and strength.

Ready to install

Supplied with jointing compound, end caps, and crimp die information for easy field installation.

Versatile for critical applications

Ideal for solar farms, substations, industrial switchgear, and renewable energy cable transitions.

- Cable Size: 400mm²

- Stud Size: 12mm

- Construction: Friction-welded aluminium barrel to copper palm

- Corrosion Protection: Electro-tinned copper to BS standard

- Accessories: Supplied with jointing compound and end cap

| Specifications | |

|---|---|

| Cable Size | 400mm² |

| Stud Size | 12mm |

| Dimensions (A–J) | A: 26mm, B: 85mm, C: 40mm, D: 36mm, E: 12mm, J: 153.5mm |

| Material | Electrical grade aluminium + electro-tinned copper |

| Crimping Test Force | 2.0x10⁵ N (300–630 mm² range) |

FAQs.

What are bimetal lugs used for?

They are used to connect dissimilar metals (aluminium to copper) safely in electrical installations, helping prevent galvanic corrosion.

Are these lugs suitable for renewable energy systems?

Yes. They're widely used in solar farms, wind turbines, and substations where mixed conductor types are common.

How are bimetal lugs installed?

They are crimped using the specified die set and come pre-filled with jointing compound and end caps for easy application.

Are these lugs resistant to corrosion?

Yes. All copper parts are electro-tinned to prevent corrosion and oxidation, especially in humid or coastal environments.

What industries and applications is this product best suited for?

This product is ideal for:

-

Power Utilities & Renewables: Substations, solar/wind arrays

-

Industrial Infrastructure: Electrical panels and heavy plant

-

Marine & Offshore: Corrosion-prone cable transitions

-

Rail & Transport: Mixed-metal power supply systems

Explore similar products.

Connect with confidence.

Talk to our team about bimetal lugs that deliver durability and compliance across high-performance energy systems.